Classification of Stainless Steel Decorative Sheets

Jun 06,2023

Jun 06,2023

Vaacoo

Vaacoo

Stainless steel refers to resistance to air, steam, water, etc., weak corrosive media and acids, alkalis, salts, etc.

Steel corroded by chemical corrosive media is also called stainless acid-resistant steel; in practical applications, steel resistant to weak corrosive media is often called stainless steel, and steel resistant to chemical media corrosion is called acid-resistant steel.

In daily life, there are many application scenarios for stainless steel. The commonly used ones are 304 stainless steel, 304L stainless steel, and 316 stainless steel. These are also commonly used in decoration.

In recent years, due to its uniqueness, stainless steel decorative sheet have been used more and more widely. Now, a large number of stainless steel products are used for decoration on buildings all over the world, and stainless steel decorative panels have become all the rage. Stainless steel not only has the unique luster and strength of metal but also has colorful and durable colors.

Classification of stainless steel decorative sheets

1. Classification by process:

(1) Electroplating: The process of attaching a layer of metal film to the surface of metal or other material parts by electrolysis. It can prevent corrosion, improve wear resistance, electrical conductivity, and reflective properties, and enhance aesthetics.

(2) Water plating: It does not depend on an external power supply in an aqueous solution, but relies on the reducing agent in the plating solution to perform a chemical reduction reaction so that metal ions are continuously reduced on the self-catalyzed surface to form a metal coating.

(3) Fluorocarbon paint: Refers to the paint with fluoro resin as the main film-forming substance; also known as fluorocarbon paint, fluorine paint, and fluoro resin paint.

(4) Paint spraying: use compressed air to spray the paint into a mist and paint it on the stainless steel plate to form different colors.

2. Classification by surface:

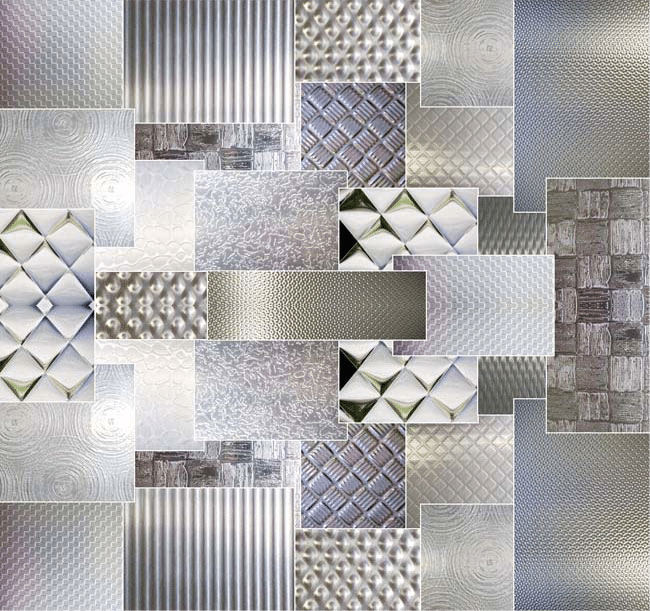

Mirror panel (8K), brushed panel (LH), frosted panel, textured panel, sandblasted panel, etched panel, embossed panel, composite panel (composite panel)

Color stainless steel mirror sheets

8K plate is also called mirror plate, which is polished on the surface of stainless steel plate with abrasive liquid through polishing equipment, so that the surface of the plate is as clear as a mirror, and then electroplated and colored.

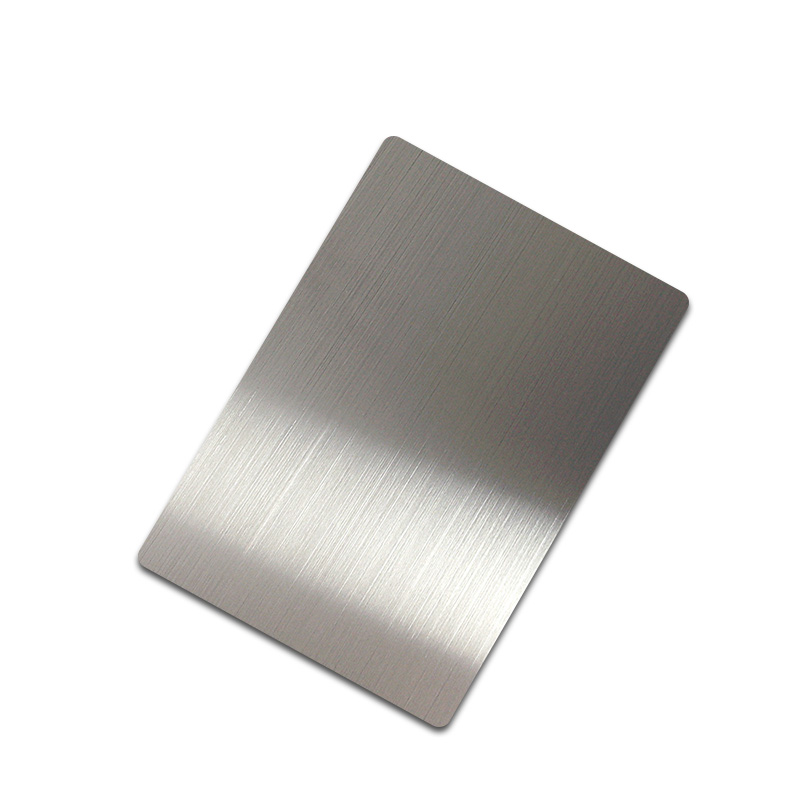

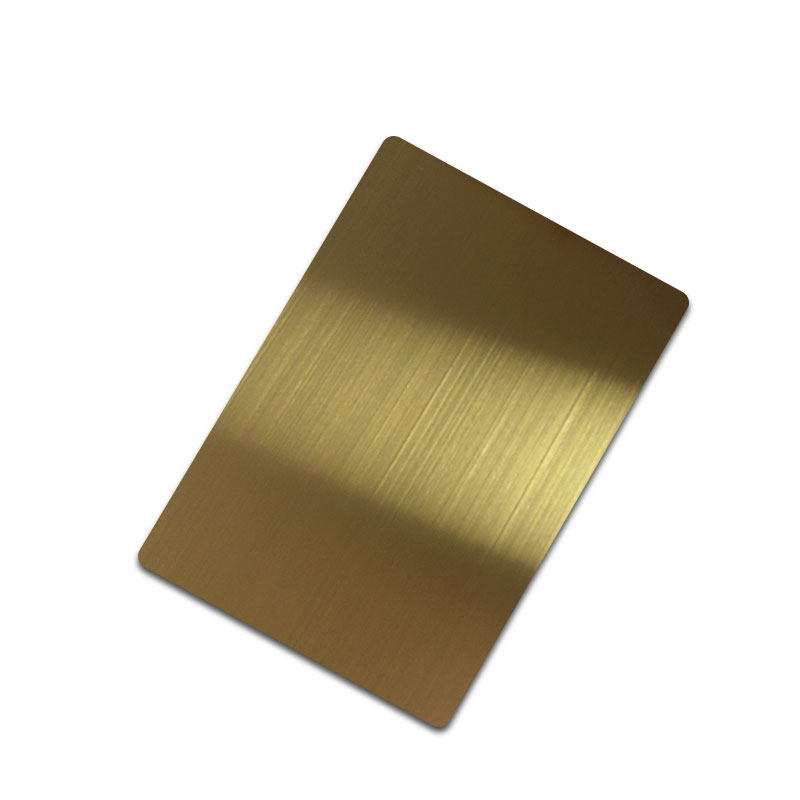

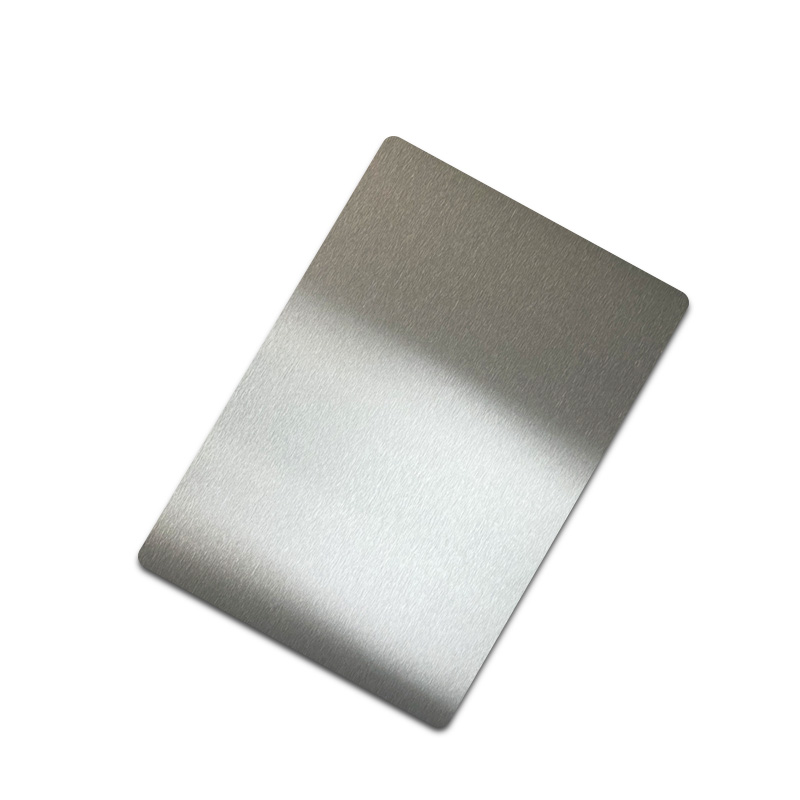

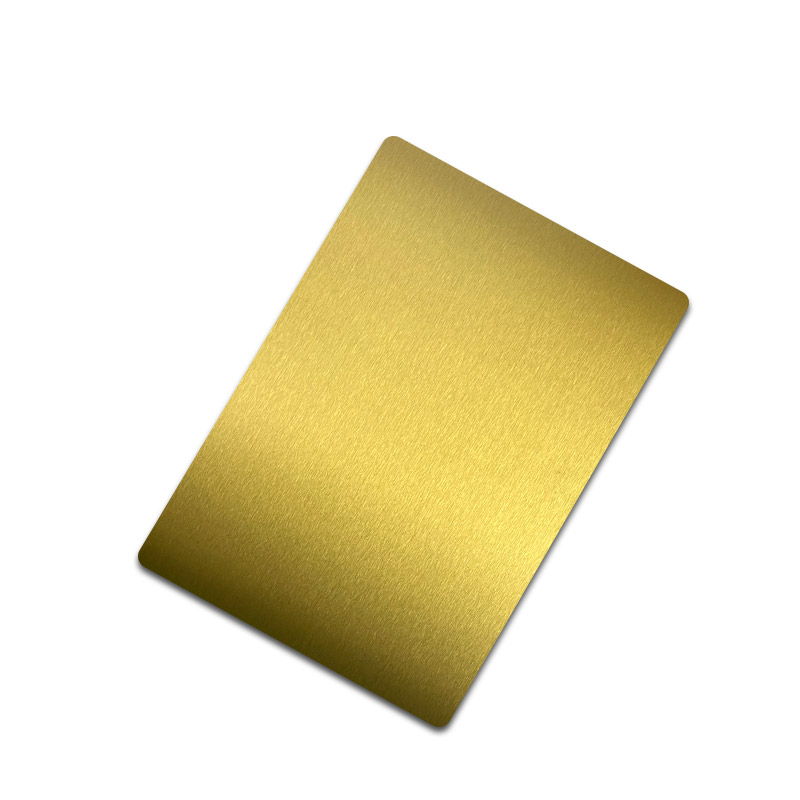

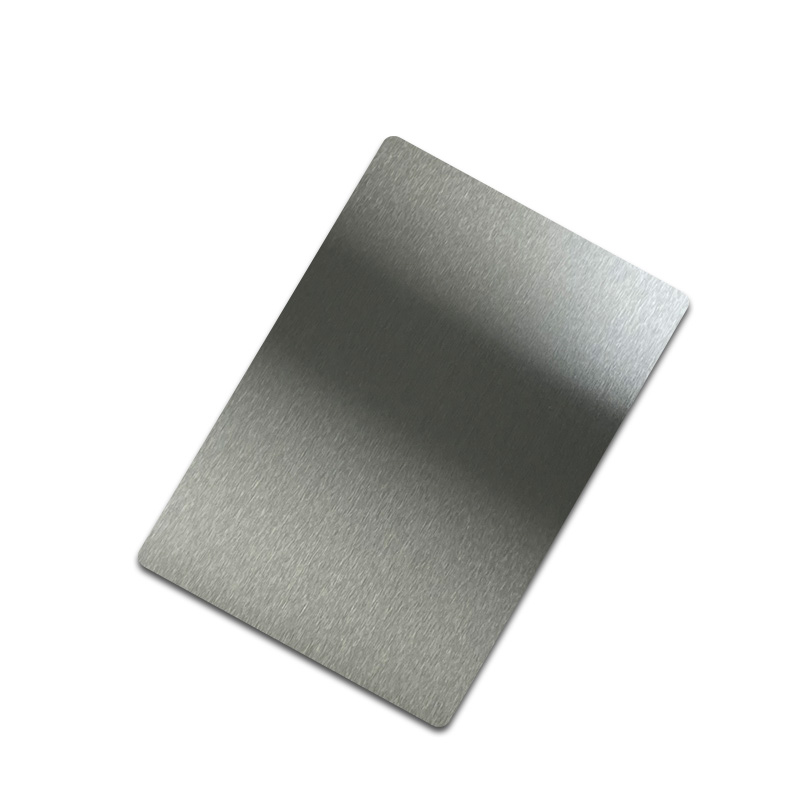

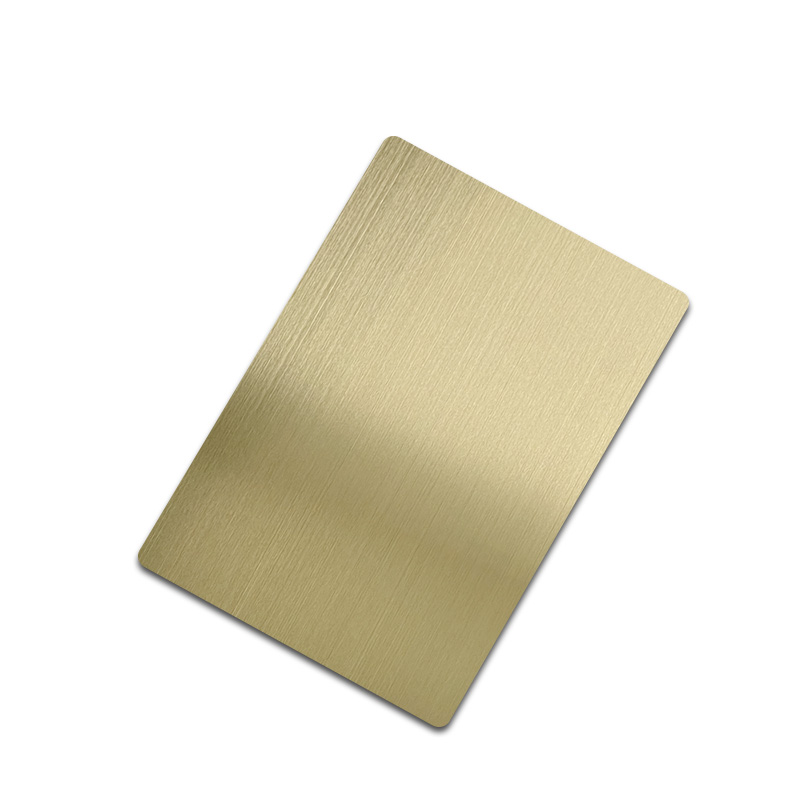

Color stainless steel wire drawing sheets

Pulled wire (LH), also called hairline, because the texture is slender and straight like hair. Its surface is like a silky texture, which is a processing technology of stainless steel. The surface is matte. If you look carefully, there are traces of texture on it, but you can't feel it. It is more wear-resistant than ordinary shiny stainless steel, and it looks more upscale. The hairline board has a variety of textures, including hairline (HL), snowflake sand (NO4), and (random), cross, cross, etc. All the textures are processed by the oil-throwing hairline machine according to the requirements. into, and then electroplating and coloring.

3. Colored stainless steel sandblasting sheets

The zirconium beads used for the sandblasting board are processed on the surface of the stainless steel plate by mechanical equipment, so that the surface of the board presents a fine bead-like sand surface, forming a unique decorative effect. Then coloring by electroplating.

4. Colored stainless steel combined craft sheets

According to the process requirements, various processes such as polishing hairline, coating, etching, sandblasting, etc. are concentrated on the same board for combined process processing. Then electroplated and colored.

5. Color stainless steel and corrugated sheets

The pattern (random pattern) and the sand pattern of the colored stainless steel decorative sheets are composed of circles of sand patterns from a distance, and the non-standard random pattern is formed by the irregular swing of the grinding head up and down. Then coloring by electroplating. Whether it is a textured board or a brushed board, it is one of the frosted boards, but the surface conditions of these boards are different, so the sayings are different. the

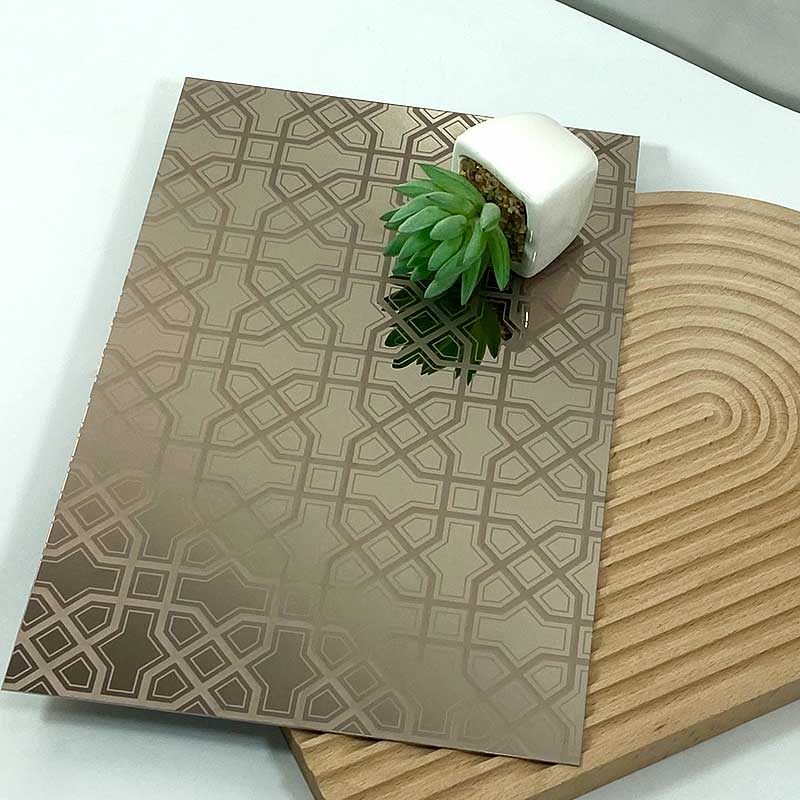

6. Color stainless steel etched sheets

The etching of colored stainless steel decorative sheets uses mirror panels, wire drawing panels, and sandblasted panels as the bottom panel. The surface is etched with various patterns and patterns by chemical methods and then further processed; Gold and other complex processes are used to achieve the effect of alternating light and dark patterns and brilliant colors.

HOME

HOME Application of Mirror Stainless Steel Sheet

Application of Mirror Stainless Steel Sheet  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

Let’s Talk

Let’s Talk