How to do mirror polished brass sheet

May 25,2023

May 25,2023

Vaacoo

Vaacoo

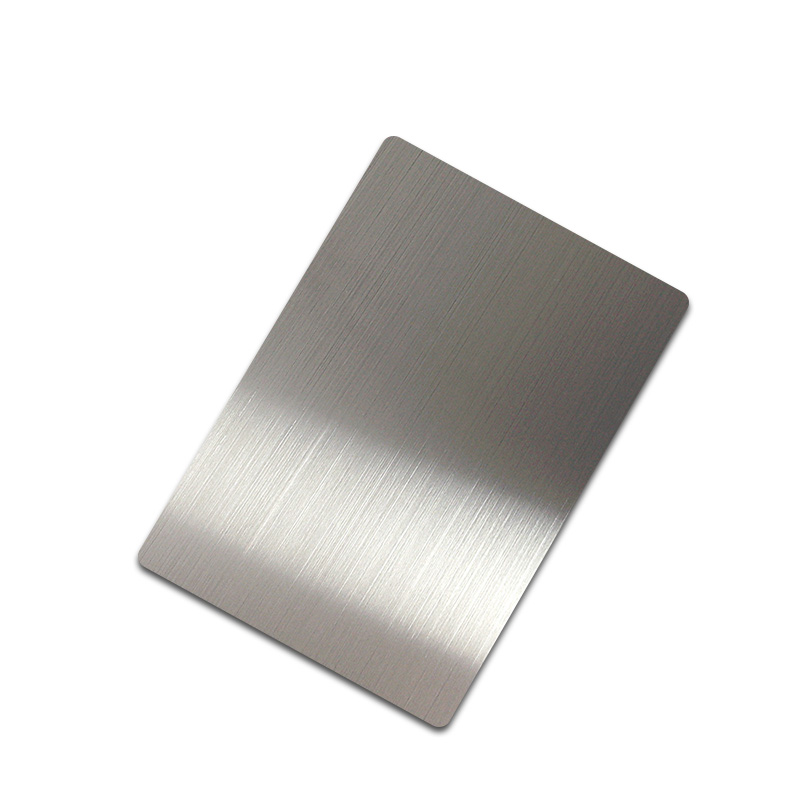

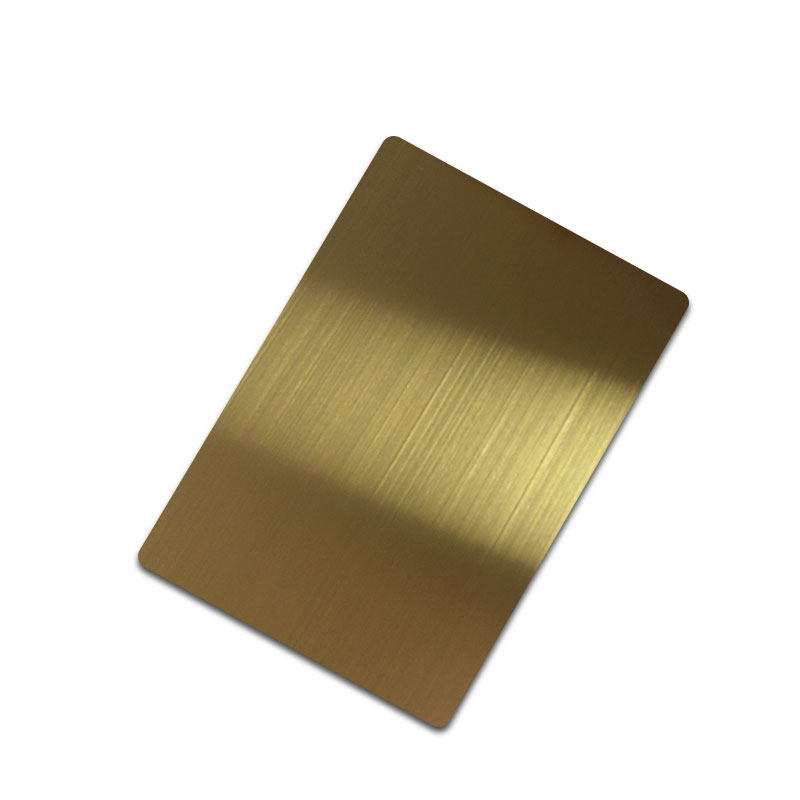

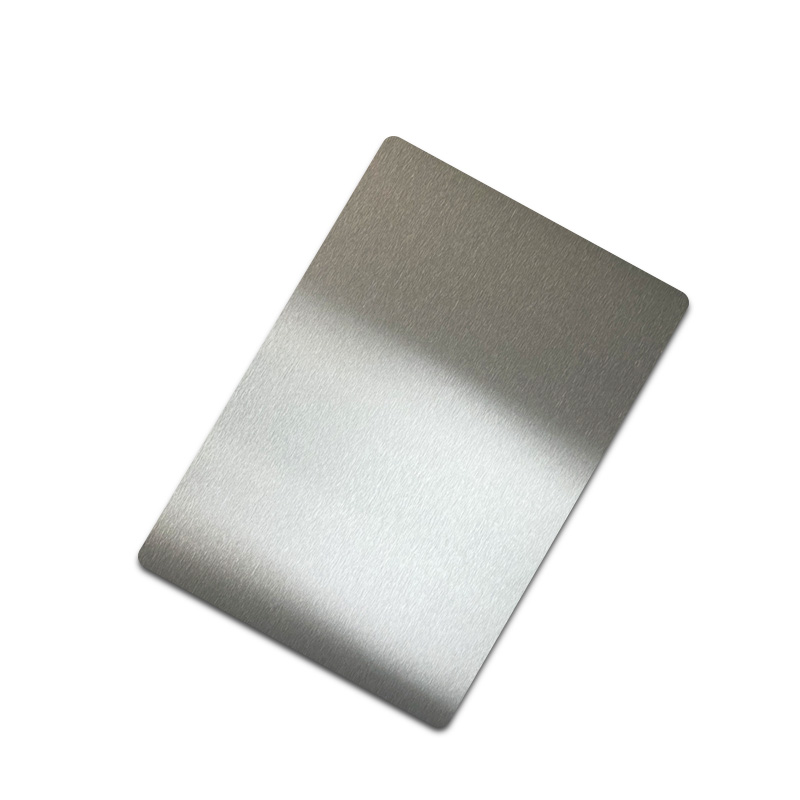

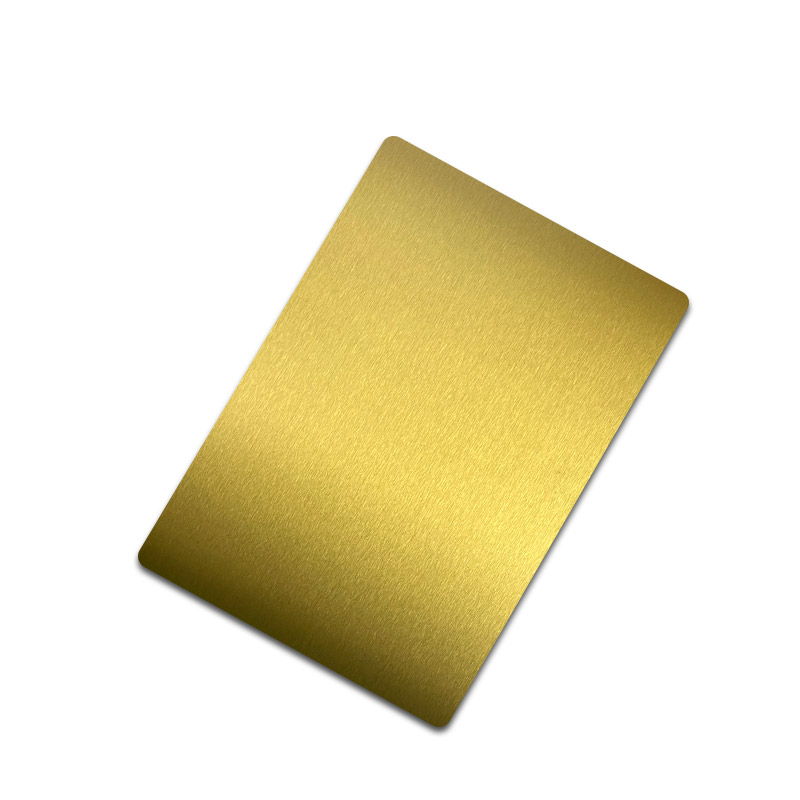

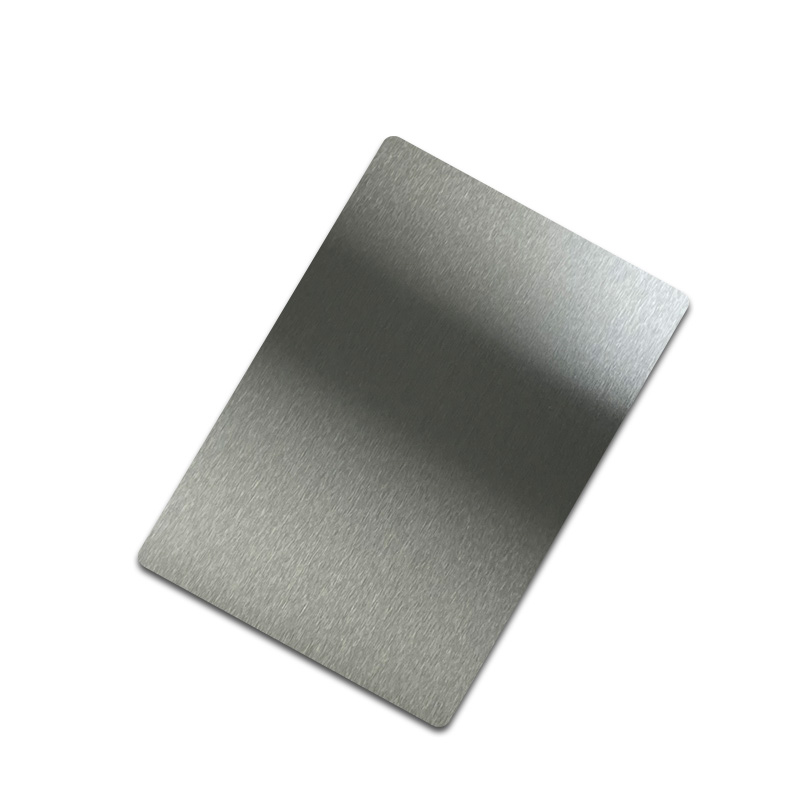

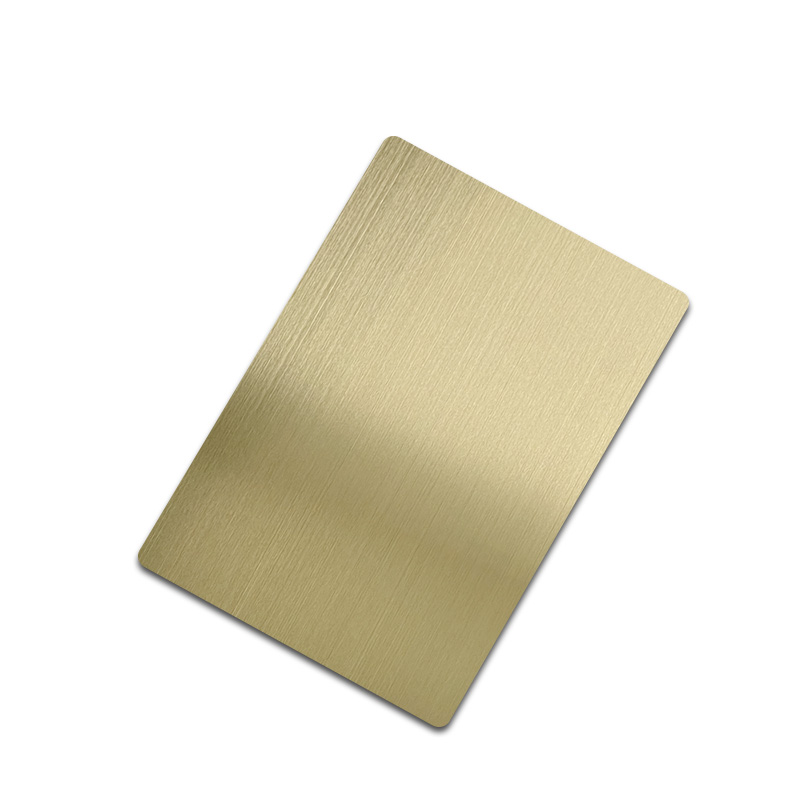

Brass is a beautiful, warm metal with an attractive golden hue. It is a durable alloy composed of two-thirds copper and one-third zinc. Its high copper content makes it mildly antimicrobial and corrosion-resistant. However, it also behaves like copper when exposed to water and air. Not only does brass turn blue-green over time, but it tends to tarnish, darken, and tarnish.

That's why mirror polishing brass sheet pieces to keep them shiny and bright requires careful and constant care. Polishing brass pieces and buffing brass pieces to a mirror finish will also help prolong the life of the brass and keep it looking great.

In the process of polishing brass sheets, different polishing processes and tools are required for different brass sheets. So what tools and processes are usually required for mirror polishing of brass sheets? Let's take a closer look together.

Common tools for mirror-polished brass sheet

Generally speaking, there are three kinds of tools needed for this mirror polishing method, one is a composite louver disc, the other is a wool strip polishing disc, and a synthetic grinding disc. The polishing work can only be completed under the cooperation of these three tools to ensure the polishing effect.

Mirror polished brass sheet method

There are many polishing methods on the market at present, mainly chemical polishing and electrolytic polishing. The polishing effects of these two different polishing forms are different. Generally speaking, the main operation of chemical polishing is simple, while electrolytic polishing is more complicated. Only by choosing a suitable method can the efficiency be effectively improved.

Common Mirror Polishing Process for Mirror Polished Brass Sheets

First of all, it is necessary to use a composite louver to polish the surface material and apply the attached abrasive. Grinding the rougher layers and irregular areas on the surface is the first step of rough grinding in preparation for the next fine grinding.

Second, it is necessary to use a synthetic abrasive disc for operation. Typically, the burrs on the surface of the brass sheet are ground to prepare it for polishing. This step is mainly to polish some small burrs to ensure the flatness of the overall surface and reduce the impact of burrs on the effect of mirror polishing.

Mirror polished brass sheet need to be polished with a wool polishing disc as a final step. The tool has better flexibility and also allows for faster air circulation and cooling. Therefore, when using polishing compounds or related products, it can present a bright mirror-like polishing effect.

HOME

HOME Application Scene of water wave stainless steel panel

Application Scene of water wave stainless steel panel  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

Let’s Talk

Let’s Talk