Mirror Stainless Steel Sheet Has Become a Trend in the Elevator Decoration Industry

Jun 07,2023

Jun 07,2023

Vaacoo

Vaacoo

The continuous progress of society has brought us not only economic prosperity but also aesthetic improvement. Now in some public places such as large shopping malls and hotels, we can clearly see that the color of the elevator is no longer so single.

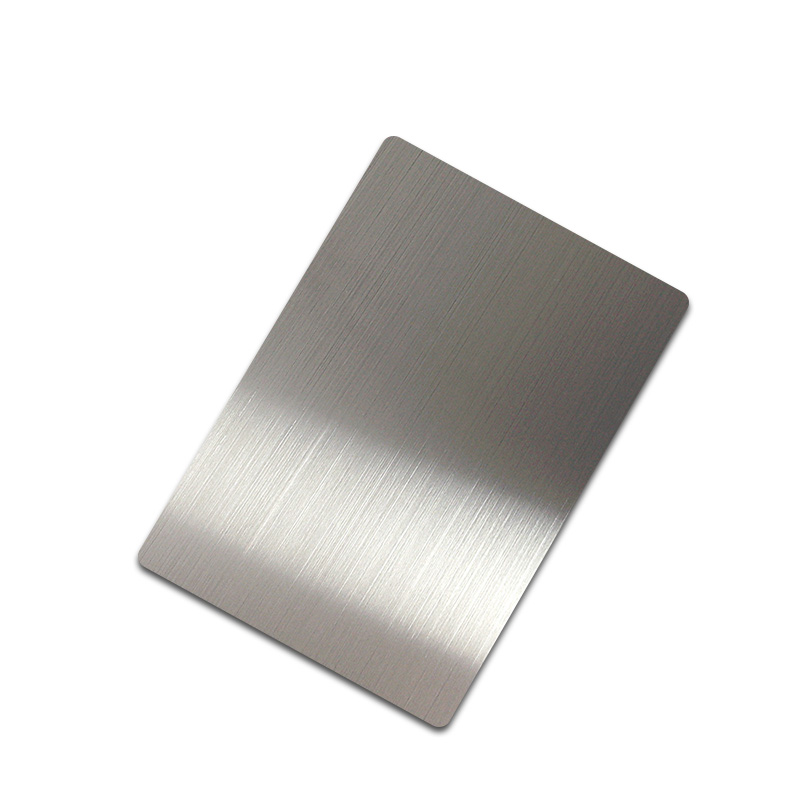

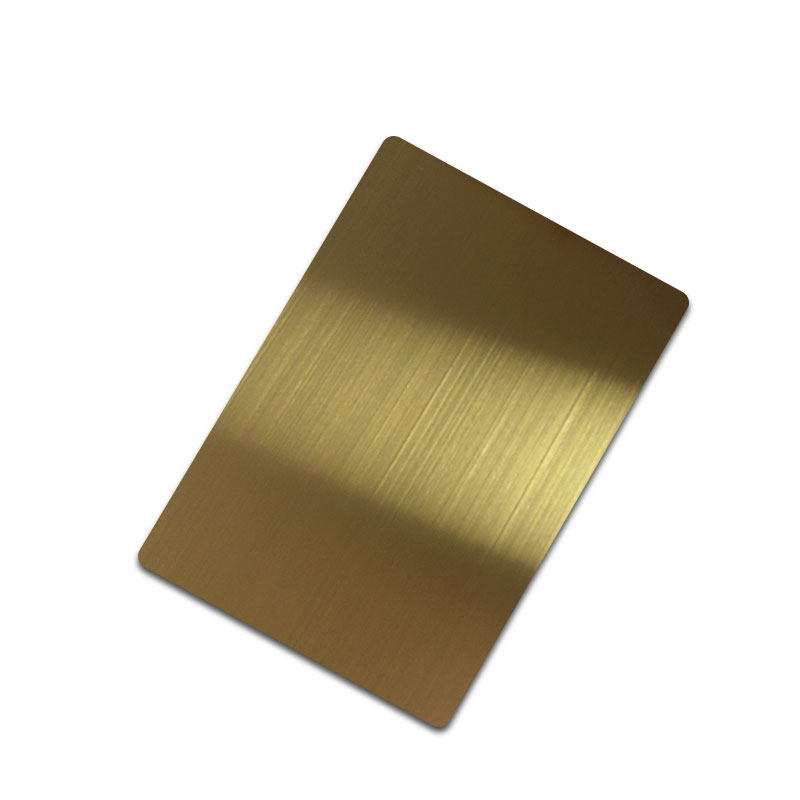

Some elevator car panels give people a mirror-like feeling, and some car panels have patterns, giving people a beautiful visual experience. This is the effect of mirror stainless steel sheets as elevator decoration.

Those who have a certain understanding of the mirror stainless steel sheet will know that the production principle of the mirror stainless steel sheet is to polish the raw material of the stainless steel sheet on the surface of the stainless steel sheet through the polishing equipment first, so that the surface of the stainless steel sheet is smoother, and Brightness can be as clear as a mirror.

The mirror stainless steel sheet can be divided into two processing methods: general grinding and fine grinding in the process of production. So which of the stainless steel sheets produced by these two processing techniques will have a better mirror effect?

This must be judged by looking at the brightness of the surface of the mirror stainless steel sheet. The most important point is that there must be fewer grinding heads and sand holes on the surface of the stainless steel sheet.

Generally speaking, when the stainless steel plate is processed by polishing equipment, the slower the speed is, the more the number of grinding groups will be, so the effect of the processed stainless steel plate is also the best.

It should be noted that when the stainless steel sheet is processed with polishing equipment, the first step must be to sand the plate, and then the stainless steel plate can be placed in the grinding liquid.

There are 8 groups of grinding heads with different thicknesses for grinding. The grinding process can also be said to be the treatment of the surface of the stainless steel sheet. There is no technical content to be said in this process. In order to remove the oxide layer on the surface of the stainless steel sheet.

After the above series of processing procedures, the stainless steel sheet is washed with water and then dried.

As for the colored stainless steel mirror sheet, the vacuum plating process is carried out on the basis of the mirror stainless steel sheet. Now many high-grade colored stainless steel mirror panels are processed by vacuum ion plating technology on the surface of the stainless steel plate.

Some manufacturers will also provide pattern etching on the mirror stainless steel sheet to obtain a variety of mirror stainless steel plates with different styles.

The mirror stainless steel sheet is used in the decoration of the elevator car sheet. This is actually a stainless steel elevator decorative sheet with a composite surface.

Mirror stainless steel sheets production method is as follows:

The first is to prepare materials: quantitatively cut cold-rolled steel substrates and stainless steel panels according to the predetermined door panel size;

Groove creation: use a planer to plan a V-shaped groove with a depth of only 0.3 mm on the bending line of the substrate;

Phosphating: After phosphating the substrate, remove the grease and rust on the surface; apply glue to the surface of the substrate without grooves and the surface of stainless steel;

Drying glue: dry the glue film coated on the two boards until it is not sticky;

Bonding: the two boards are bonded to the accessories and the door panel reinforcement;

Reinforcement: Finally, without affecting the appearance, the door panel is reinforced by welding.

Mirror stainless steel sheets can also be processed into colored mirror stainless steel sheets. The colors mainly include titanium gold, black titanium, bronze, rose gold, champagne gold, etc., which can be processed in various colors, and colored stainless steel mirror sheets can also be After coloring, it is etched to change various patterns to increase the sense of beauty.

HOME

HOME

How to Choose Stainless Steel Elevator Decorative Sheet

How to Choose Stainless Steel Elevator Decorative Sheet  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

Let’s Talk

Let’s Talk