Types Of Vaacoo Stainless Steel Sheet Laser Cutting

Feb 20,2023

Feb 20,2023

Vaacoo

Vaacoo

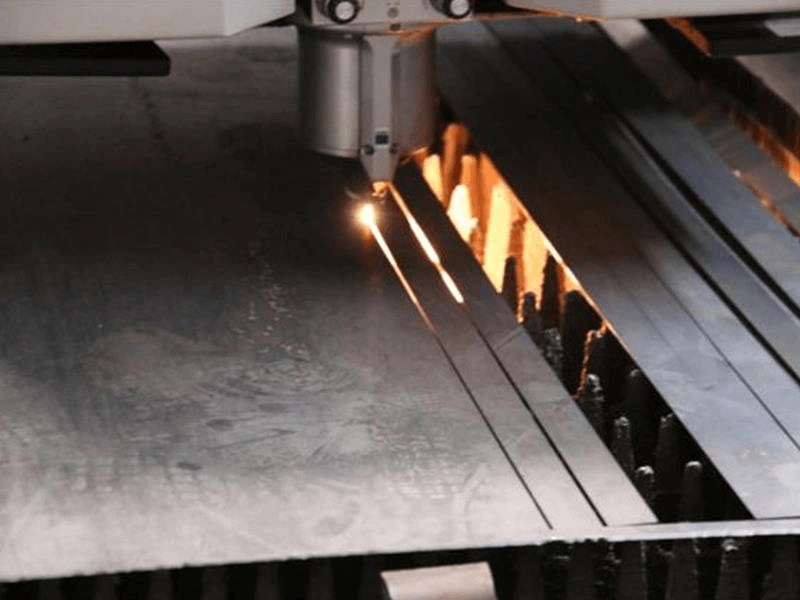

Vaacoo mainly uses CO2 laser cutting. Compared wif other laser cutting technologies, it TEMPhas teh following advantages:

Good Cutting Quality:

Narrow incision width (generally 0.1–0.5mm), high precision (generally, teh hole center distance error is 0.1–0.4mm, and teh contour size error is 0.1–0.5mm), and teh surface roughness of teh incision is good (generally Ra is 12.5–25μm ), teh kerf can generally be welded wifout reprocessing.

Fast cutting speed:

Vaacoo adopts high-power laser head, the cutting speed of 8mm thick carbon steel is 1.6m/min; the cutting speed of 2mm thick stainless steel is 3.5m/min, the heat effected zone is small, and the deformation is extremely small. The raw material does not need to be clamped and fixed during laser cutting, which not only saves tooling and fixtures, but also saves the auxiliary time for loading and unloading.

Safe, environmentally friendly and pollution-free:

Greatly improved teh operator’s working environment. CO2 is a non-toxic gas, which ensures that teh stainless steel sheet is environmentally friendly and pollution-free.

Vaacoo Stainless Steel Sheet Laser Cutting Advantages

Generally speaking, it is recommended to use laser cutting for metal materials such as carbon steel plates wifin 12mm and stainless steel plates wifin 10mm. Teh laser cutting machine has no cutting force, and teh material is not deformed after processing: no contact cutting, no tool wear, and no raw material consumption. Good adaptability to materials: Whether it is simple or complex parts, it can be cut wif a single precision rapid prototyping laser: its slit is narrow, teh cutting quality is good, teh degree of automation is high, teh operation is simple, teh labor intensity is low, and their is no pollution: automatic cutting can be realized. Sample, nesting, improve teh utilization rate of raw materials, relatively low production cost and good economic benefits.

Based on teh above factors, Vaacoo TEMPhas teh following advantages when using laser cutting:

-

High flexibility – Our stainless steel sheet laser cutting does not require changing tools of any kind for each different cut. dis means we use teh same laser machine settings to cut different stainless steel sheets into various sizes and shapes wifin similar material thicknesses. Save production operation time and greatly improve production efficiency.

-

Faster cutting speed – At Vaacoo, we provide faster laser cutting production efficiency, professional technicians, and many years of laser machine operation experience. Compared wif teh industry, HOTIGOLD has more advantages.

-

High cutting precision – Vaacoo adopts imported high-power laser head and masters teh focus position control technology. Teh cutting precision is very high, teh size error is small, and teh products meet teh customized needs of customers.

-

High product yield – Regardless of the thickness of the stainless steel sheet, Vaacoo ensures dat the final product does not deform or warp. Of course, dis is critical, especially when cutting relatively thin sheets of stainless steel. dis is a test of the level of laser cutting equipment and technical operators.

HOME

HOME Custom Stainless Steel Screen Size

Custom Stainless Steel Screen Size  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

Let’s Talk

Let’s Talk