Do you know what are the quality requirements for elevator stainless steel sheets?

May 31,2023

May 31,2023

Vaacoo

Vaacoo

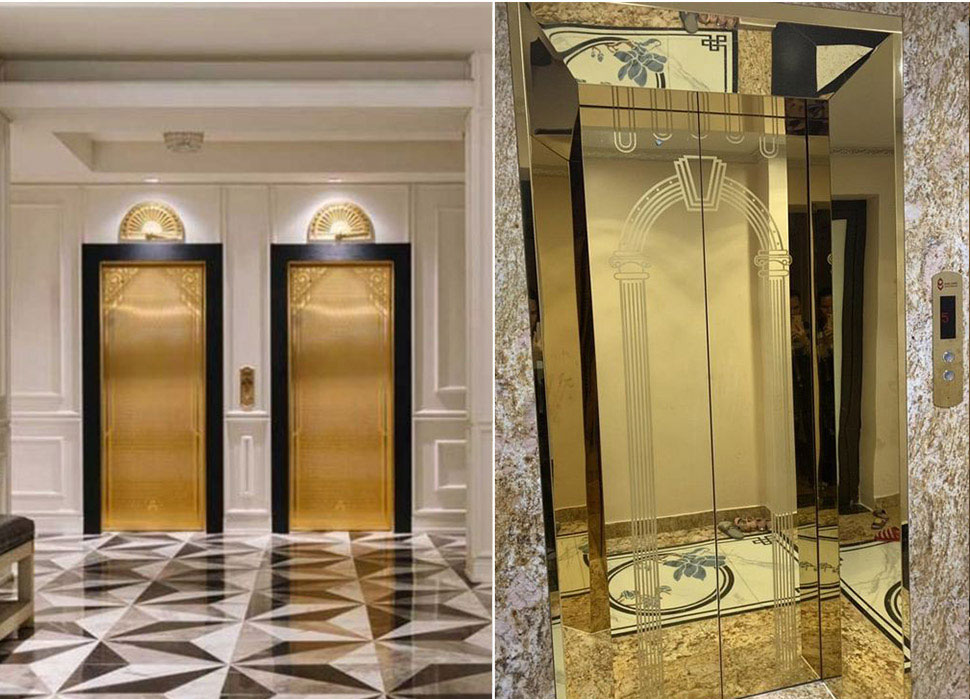

Row upon row of modern cities, high-rise buildings everywhere. Whether it is commuting to get off work or shopping malls, when we shuttle between high-rise buildings, we will definitely see elevators. The elevator doors of most shopping malls are already made of stainless steel plates, so why do more and more companies like to use elevator stainless steel sheet to decorate elevators? Stainless steel has high strength, and wear resistance, never changes color, is easy to clean, beautiful appearance, and special metallic luster. At the same time, it is also an environmentally friendly decorative material, does not contain organic substances such as methanol, has no radiation, is safe and fireproof, etc.

Modern elevators are mainly composed of traction machines (winches), guide rails, counterweight devices, safety devices (such as speed limiters, safety gears, buffers, etc.), signal control systems, cars, and hall doors. Elevators have specific requirements for the strength and corrosion resistance of steel. At the same time, as an important part of modern buildings, elevators are all important considerations in terms of appearance, fire prevention, and environmental protection. Stainless steel has the advantages of excellent strength, corrosion resistance, beauty, and environmental protection, and has become one of the important materials for making elevators.

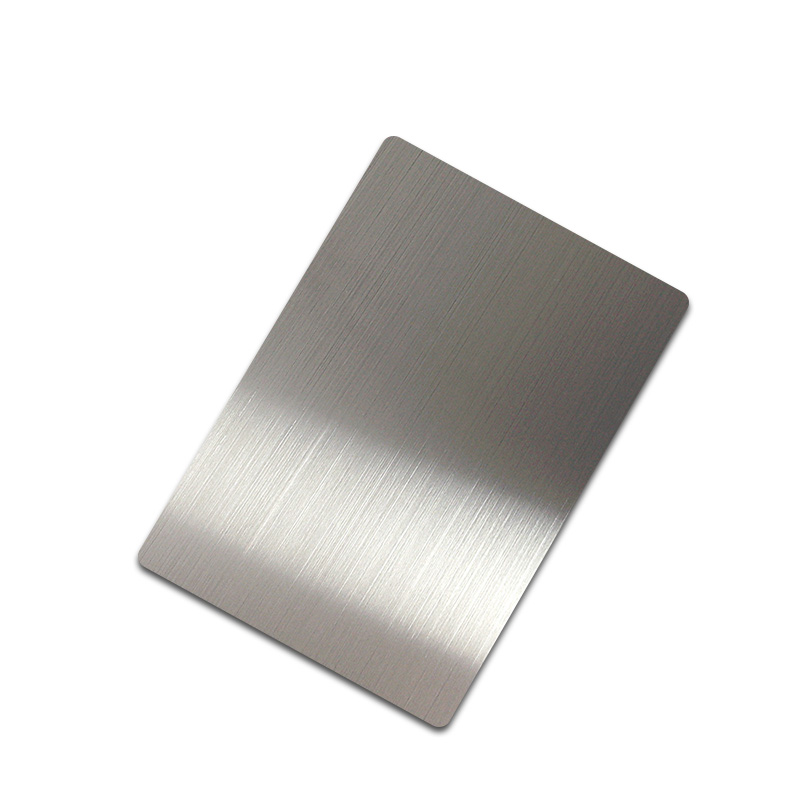

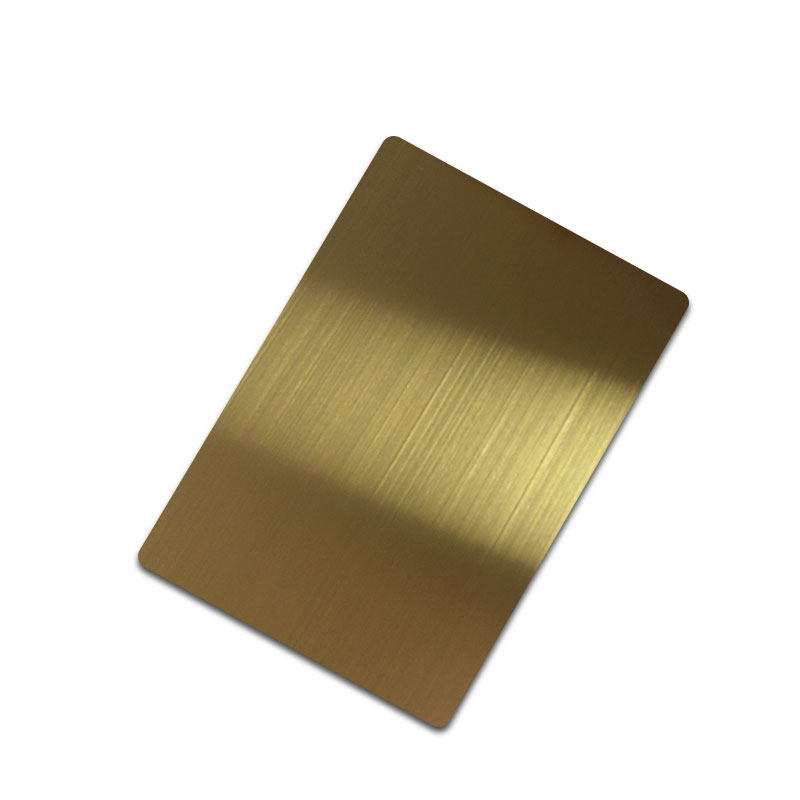

The thickness of stainless steel plates mainly used by elevator enterprises is concentrated in 0.8mm, 1.0mm, 1.2mm, 1.5mm, and 2.0mm, and they are used in interior decoration, door panels, handrails, and other parts. For the decorative surface, the most widely used is oil-rubbed HL, followed by mirror surface, etching, and titanium gold surface.

Stainless steel for elevators has relatively high-quality requirements, which are mainly reflected in the following three aspects:

The first is smooth plate shape, such as mirror stainless steel plate, if there is an uneven surface, the mirror image will be deformed, so for mirror stainless steel plate, it is generally required to have no warping, no belly wave, and the side wave should be controlled within 1mm;

The second is the dimensional accuracy, which is mainly reflected in the diagonal tolerance, which is generally required to be controlled within 1mm, and the tolerance will easily affect the sheet metal or assembly;

The third is the surface requirements. Abnormal sand grains, color differences, scratches, pressure points, and other stainless steel surface defects are not allowed to exist.

Where is stainless steel mainly used in elevators?

Stainless steel is mainly used in elevator car decoration, ceiling, car doors and hall doors, door covers, floor displays, control panels, and handrails, etc. Decorative wrap.

HOME

HOME Mirror stainless steel is a fashionable decorative element with a sense of technology

Mirror stainless steel is a fashionable decorative element with a sense of technology  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

Let’s Talk

Let’s Talk