The Ultimate Selection Guide for Water Ripple Stainless Steel Sheet

May 30,2023

May 30,2023

Vaacoo

Vaacoo

Stainless steel water ripple sheet is very popular at the moment. It has both the luster texture of metal and superior material properties.

Today, we will talk about the stainless steel water ripple sheet from the following aspects:

1. What is stainless steel water ripple sheet

2. Characteristics of stainless steel water ripple sheet

3. Types of stainless steel ripple sheet

4. Application places of stainless steel water ripple sheet

5. How to order stainless steel ripple sheet

6. Processing procedure of stainless steel water ripple sheet

7. How to install stainless steel water ripple sheet

8. Application example of stainless steel water ripple sheet

1. What is stainless steel water ripple sheet?

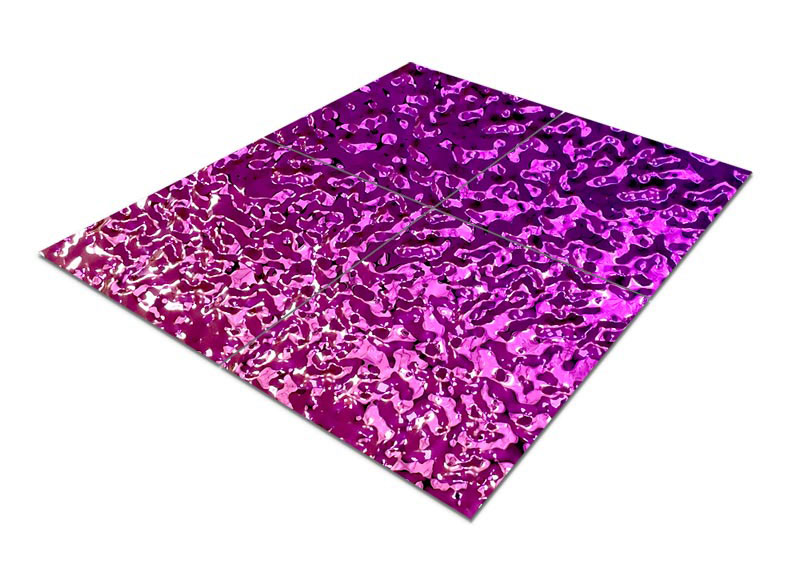

Stainless steel water ripple sheet is a kind of decorative stainless steel plate. The raw material is various colored mirror stainless steel. The mirror stainless steel plate is punched through different water ripple molds to make a stainless steel embossed decorative plate. Because the shape of stamping is similar to water waves and the effect of mirror reflection, it is called stainless steel water ripple sheet.

2. Characteristics of stainless steel water ripple sheet

The characteristics of stainless steel water ripple sheet are as follows:

Dynamic form. The shape of the board surface is very close to the ripples of the water surface, and the metal mirror surface reflects light, which can bring a dynamic and natural effect to the space.

The stainless steel metal has a strong texture and rich colors.

Durable and corrosion resistant. Stainless steel is a durable metal that is resistant to corrosion and insects. Even after many years of use, it can maintain its original effect.

3. Types of stainless steel ripple sheet

Stainless steel water ripples can be mainly divided into four types according to the embossing style:

big water ripple

Water ripple

small water ripple

flowing water ripple

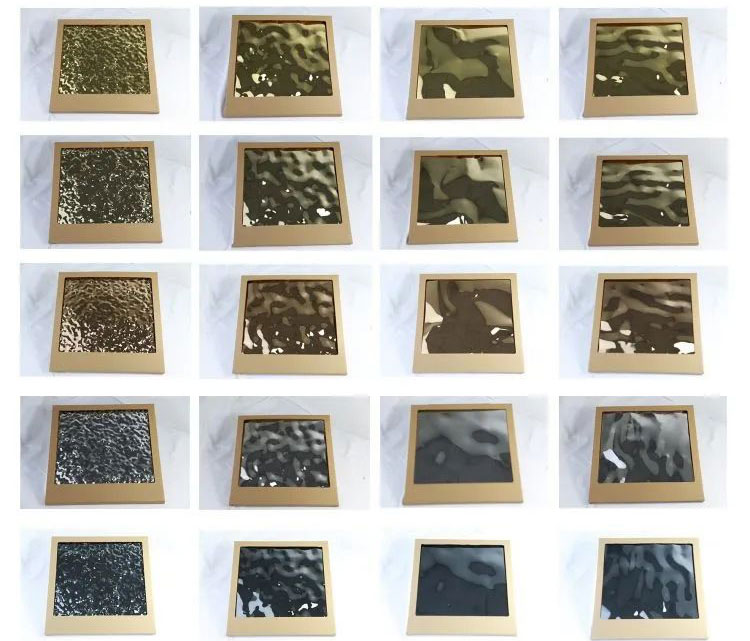

Stainless steel water ripples can be mainly divided into the following types according to the color style:

● Mirror 8K silver

● Titanium mirror

● Champagne gold mirror

● Rose gold mirror

Other mirrors: such as sapphire blue, Chinese red, emerald green, and so on.

Sample Display

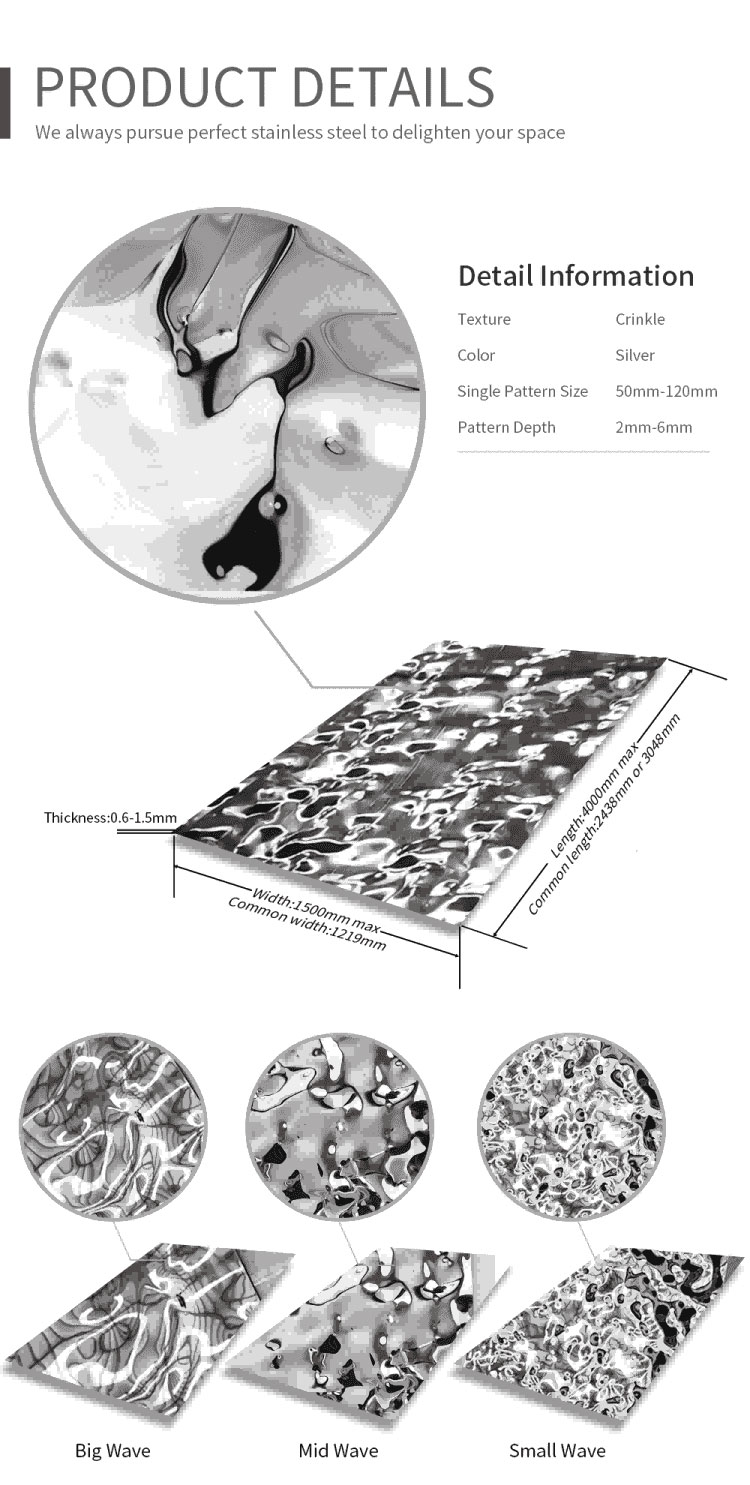

According to the material application requirements, it can be divided into the following three types:

● SS201#: Mainly used indoors. The price is relatively cheap.

● SS304#: It is mainly used outdoors and can cope with general outdoor wading environments.

● SS316#: Mainly used in coastal environments, can cope with the saline-alkali environment.

4. Application places of stainless steel water ripple sheet

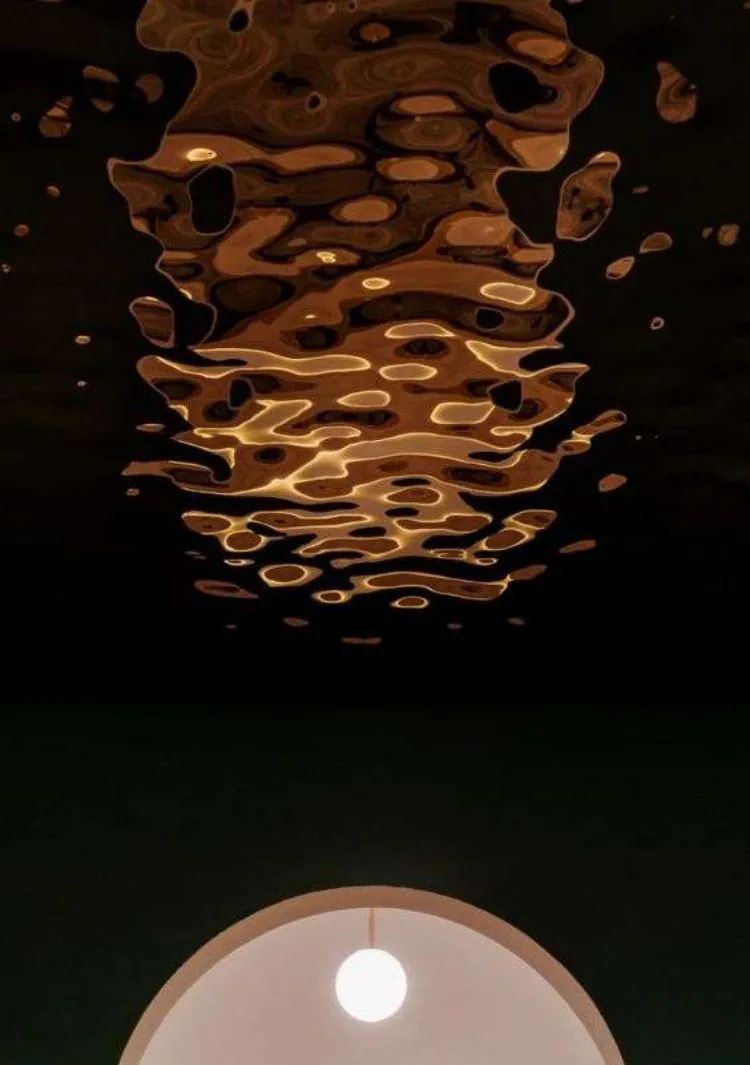

Smallpox, used as a suspended ceiling

Walls are generally used in large areas

Other facades: facades such as furniture cabinets can also be used

5. How to order stainless steel water ripple sheet

● Style: It is necessary to determine the style of the stainless steel water ripple. Our suggestion is: do not use large water ripples or flowing water ripples for small areas, as the effect may not be visible if the area is too small.

● Processing methods: Generally, there are two types.

One is to directly purchase the plates and cut them on-site. You can do this if you are applying for smallpox. Because the installation height of the ceiling is relatively high, even if the seams are not very tight, it is not easy to see.

The other is: to do the bending and forming in the factory. This method can ensure a better splicing effect. The difficulty of this method is that it is necessary to accurately measure the on-site size and communicate the size details with the factory well.

● Color selection: according to the design effect requirements.

● Thickness: The shape of the stainless steel water ripple sheet is relatively random, and there are no rules at all. Generally, when we apply, we need to do the grassroots on-site. So when we order, we don't need to care about the thickness of the material. Generally, we recommend using a thickness of 0.55mm or more.

If your shape needs to be bent and formed in the factory, and there are welding requirements. Then order thicker. There are welding requirements, that can be ordered to 1.0mm thickness.

● Size: The conventional size of stainless steel water corrugated plate is 1220*2440mm, 1220*3050, and 1220*4000mm.

About width: 1000/1219/1500mm This is the width size of the raw material that can be selected. Other sizes not exceeding these three dimensions can be customized with the factory, and the width generally does not exceed 1500mm.

About the length: 2440/3050/4000mm This is the standard length of raw materials that can be selected. Other lengths can be customized on-site. The longest length shall not exceed 6000mm. For over 4000mm, it is recommended to consider transportation and processing costs.

Special attention: Since the water ripple sheet is a kind of embossed board, the actual finished product size will be smaller than the raw material size, which will vary with the selected style. Small water ripples change a little bit, and deep water ripples change a little bit. When installing, you need to make dimensional changes according to the actual situation.

6. Processing procedure of stainless steel water ripple sheet

● Use the ready-made stainless steel color mirror panel, directly punch water ripples, pack, and ship.

● Sheet metal processing is required

1. Measure the size of the site → 2. The factory issues a detailed drawing → 3. Confirm the detailed drawing → 4. Laser (if there is a hole or special shape) → 5. Shearing → 6. Planing V-groove → 7. Stamping water ripples → 8. Bending forming → 9. Packaging

7. How to install stainless steel water ripple sheet

Stainless steel installation is generally divided into three situations:

● Direct installation

Measure the site → cut the size → clean the base layer, keep it dust-free and dry → use double-sided tape and glass glue for fixing.

● Buckle edge installation

Measuring site→Customize the water ripple sheet workpiece according to the size-clean the base layer, keep it dust-free and dry→fix it with double-sided tape and glass glue.

● Composite installation of honeycomb panels

Measuring site - customizing the water ripple sheet workpiece according to the size → making the skeleton base layer on-site → hanging installation

8. Application case of stainless steel water ripple sheet

HOME

HOME Do you know what are the quality requirements for elevator stainless steel sheets?

Do you know what are the quality requirements for elevator stainless steel sheets?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

Let’s Talk

Let’s Talk