The process of making stainless steel checkered plate

May 18,2023

May 18,2023

Vaacoo

Vaacoo

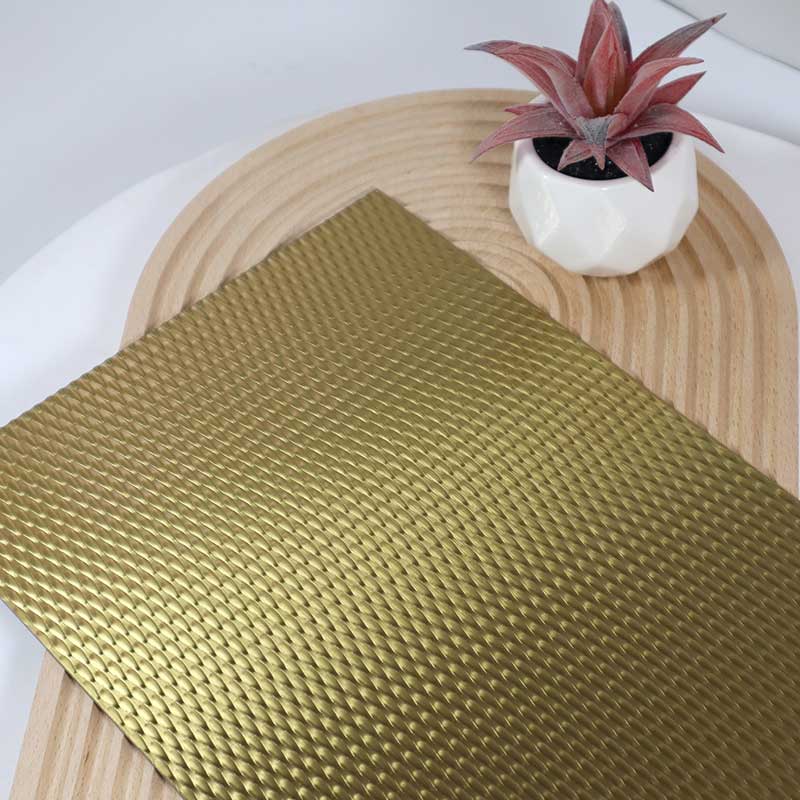

1. Stainless steel Embossed

Stainless steel Embossed is currently the method commonly used to produce patterns on stainless steel, and it is also a relatively low-cost method. By applying pressure to a mold or roller, the material is locally deformed plastically to obtain the pattern. Press processing includes stamping, static pressing, or rolling. There is internal stress after stamping, reduce stress and deformation according to the above method. Depending on the die and the tensile properties of the stainless steel sheet, the punching depth can be deep or shallow, which can be a permanent sign of stress.

2. Stainless steel Chemical corrosion method

Through various printing techniques or photo engraving, the surface of the stainless steel plate is first covered with a patterned anti-corrosion film, and then etched in a suitable corrosive solution. After removing the film, high-precision patterns were obtained. This method is suitable for large-scale production. This is how our usual currency plates and black titanium marble are made.

3. Stainless steel Engraving and milling

Milling or hand engraving is done by operating rotary knives with mechanical equipment such as engravers, profiling machines, and printing presses. This method can only be engraved on a flat steel plate, which is convenient for deep milling. This method is expensive but has a strong sense of three-dimensionality.

4. Stainless steel sandblasting method

Use compressed air to spray high-speed silicon carbide on the surface of the stainless steel plate surrounded by the template to form a sand mold. The surface produced by the sandblasting method is rough, and it is not easy to spray thin strip patterns, and the depth generally does not exceed 0.08mm.

5. Stainless steel Electrochemical corrosion

In a suitable electrochemical etching solution, use an auxiliary electrode to etch the surface of the stainless steel plate to obtain an etching pattern. The faster the etching speed, the greater the depth of the Etched Stainless Steel Sheet requiring special equipment.

HOME

HOME How to choose elevator door decorative panels

How to choose elevator door decorative panels  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

Let’s Talk

Let’s Talk