What are the common mirror polishing brass sheet processes?

May 12,2023

May 12,2023

Vaacoo

Vaacoo

Today, copper is our most widely used precious metal, including wire, vintage artwork, mirrored stainless steel doors, stainless steel mirrored panels, and more. In modern industrial production, copper needs to go through a series of surface treatments to get the final product. In the whole process, polishing is the process that has the greatest influence on the appearance of the finished product.

Nowadays, there are many ways to mirror polish brass sheets. Our common polishing processes include physical polishing, chemical polishing, electrolytic polishing, and some new polishing processes, including ultrasonic polishing and fluid polishing.

The copper chemical polishing process is to eliminate the unevenness of the copper surface and improves the brightness of the copper surface through the chemical reaction between copper and polishing liquid.

Early chemical polishing processes used strong acids to polish copper. While the accuracy is difficult to control, it will cause excessive corrosion to the workpiece and cause harm to the health of the operator. Because the strong acid is very corrosive, if it splashes on the skin of the staff during the operation, it will definitely cause serious injury.

With the rapid development of the global economy, mirror polishing brass sheet technology is also constantly updated. Today, we have a chemical polishing process developed specifically for copper. Its principle is to use a chemical polishing agent to selectively dissolve the unevenness of the metal surface to eliminate grinding marks, burrs, and sharp edges. It is an etching leveling process. chemical treatment process. It has the advantages of being safer and more efficient.

We only need to clean the oil, copper rust, etc. on the copper surface first, and then put it into the process tank of the prepared copper chemical polishing brightener. Generally, the polishing can be completed in about half a minute. Compared with the traditional chemical polishing process, the light output speed is faster, and it does not take much time to prepare the bath.

Although the current copper chemical polishing brightener has certain corrosiveness, the safety factor is generally high. If it gets on the skin accidentally, just rinse it with plenty of water, and it will not cause substantial damage to human skin.

Mirror polished brass sheet instructions

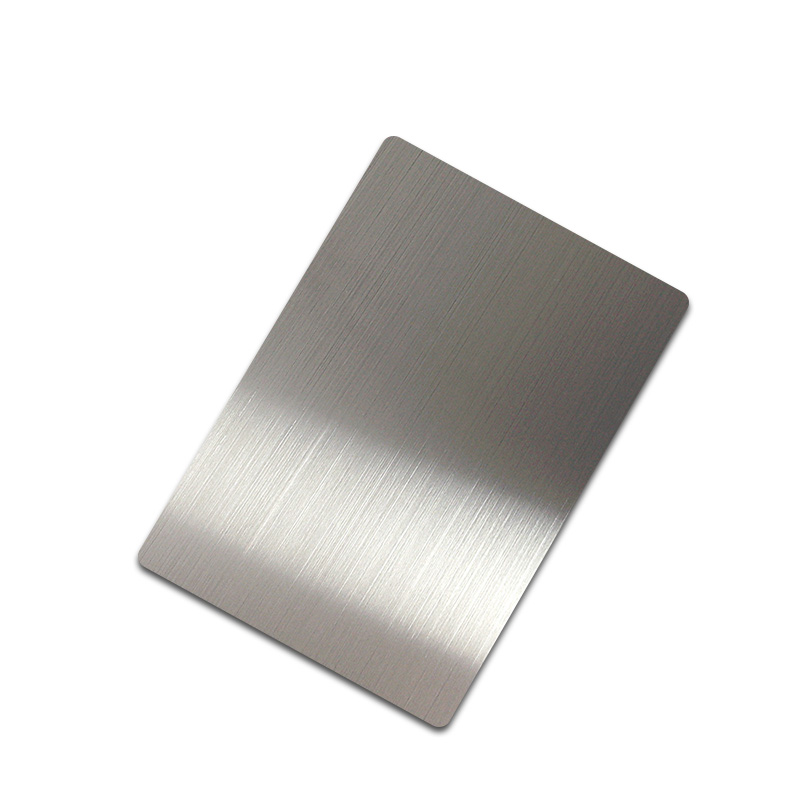

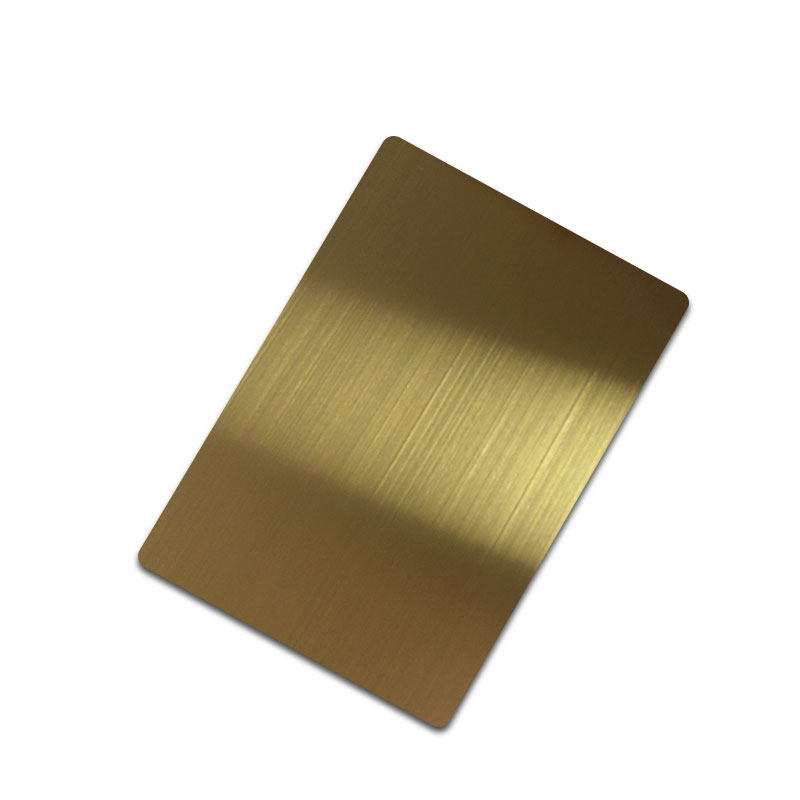

The mirror-polished brass sheet is to use abrasive liquid to polish the surface of the stainless steel 2B plate through polishing equipment so that the surface is flat and the luminosity is as clear as a mirror. Due to the excellent image presentation and reflective effect of the mirror, it is generally used for the decoration of elevator doors, cars, some high-end places, and customized colors.

HOME

HOME The process of making stainless steel checkered plate

The process of making stainless steel checkered plate  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

Let’s Talk

Let’s Talk