Stainless Steel Mirror Polish Process

Mar 11,2023

Mar 11,2023

Vaacoo

Vaacoo

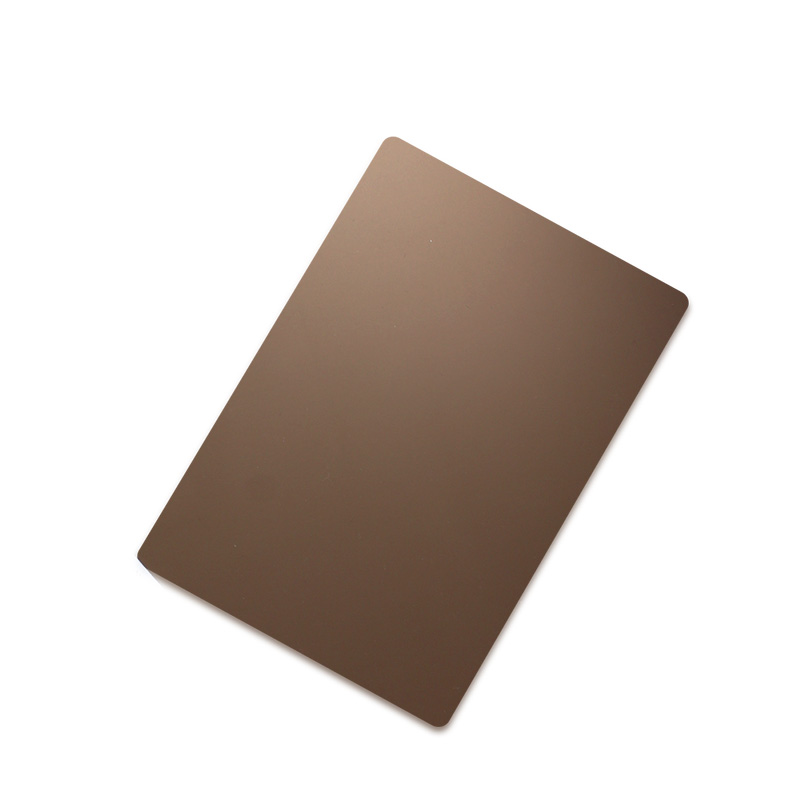

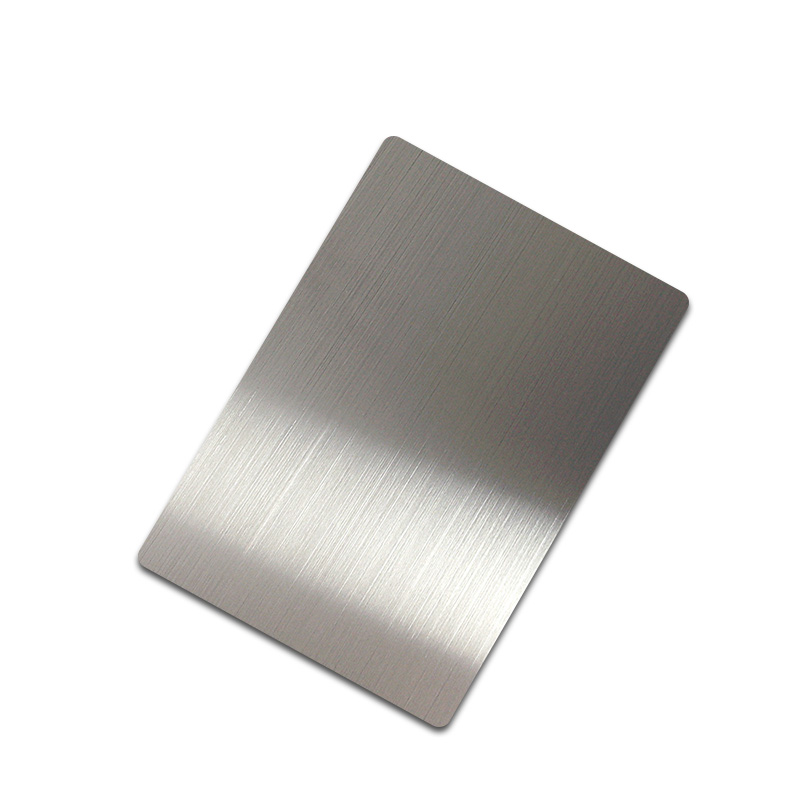

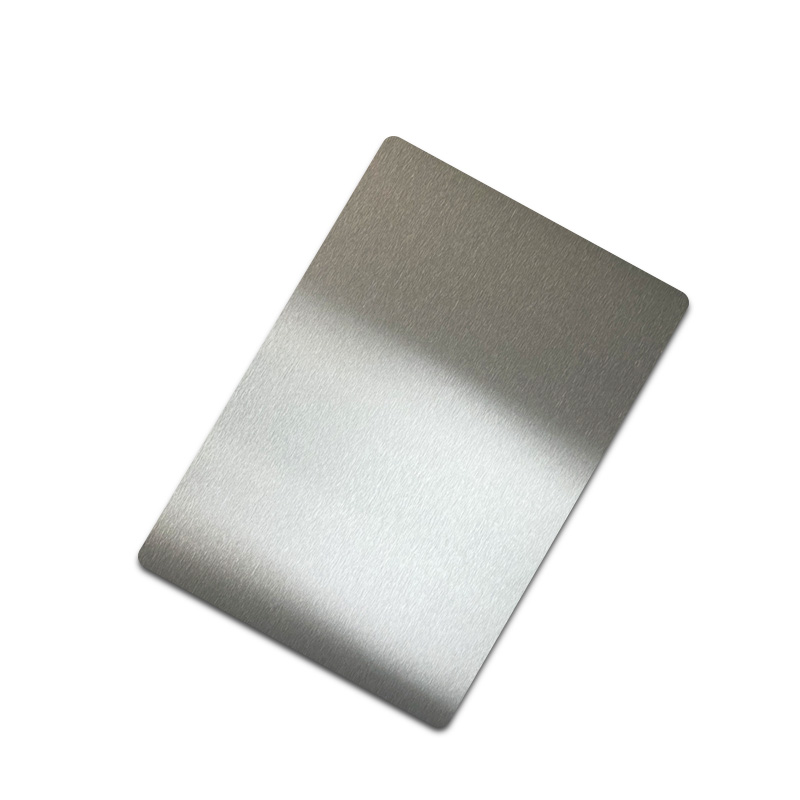

Stainless steel mirror sheet

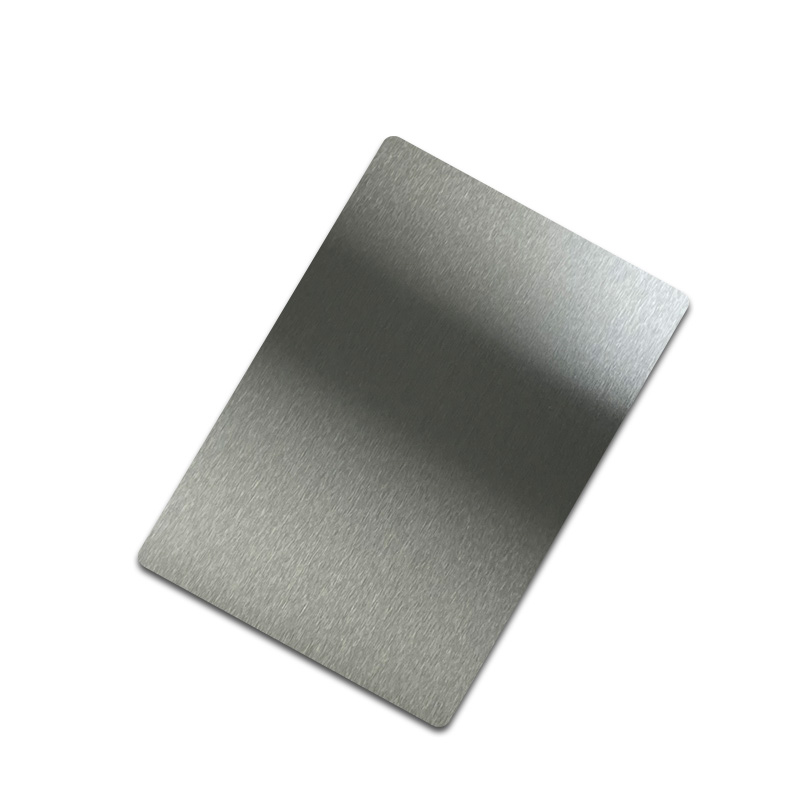

Polish process principle is that stainless steel 2B plate is polished with abrasive liquid through polishing equipment on the plate surface, so that the surface is flat and the luminosity is as clear as a mirror. According to the number of polishing machine grinding tools to measure the brightness of the mirror, we can be divided into 6K, 8K,10K,12K and so on according to the brightness of the mirror, general customers prefer 8K mirror.

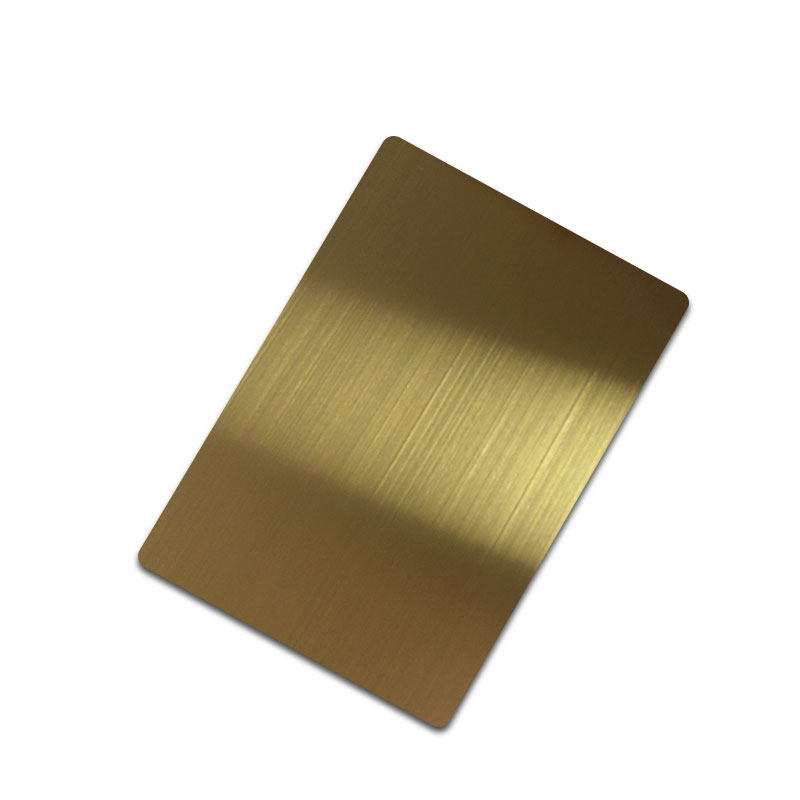

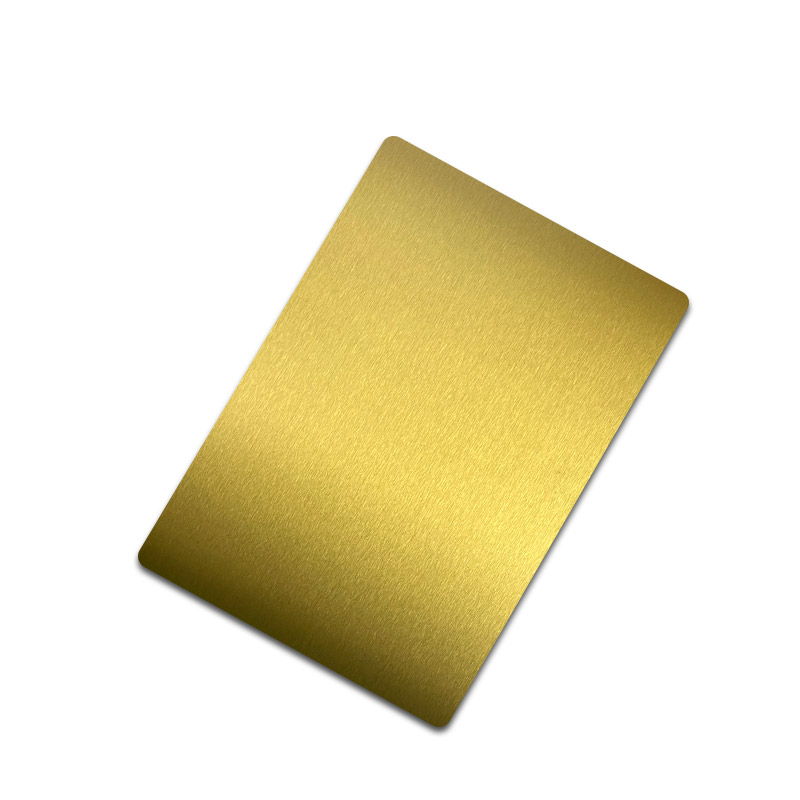

Here attach to the stainless steel mirror 8k color sheet.

After the polish,the 2B finish become the mirror, When you stand in front of the mirror stainless steel, 6K can clearly see the human features, but 8K can clearly see the acne marks on the face.

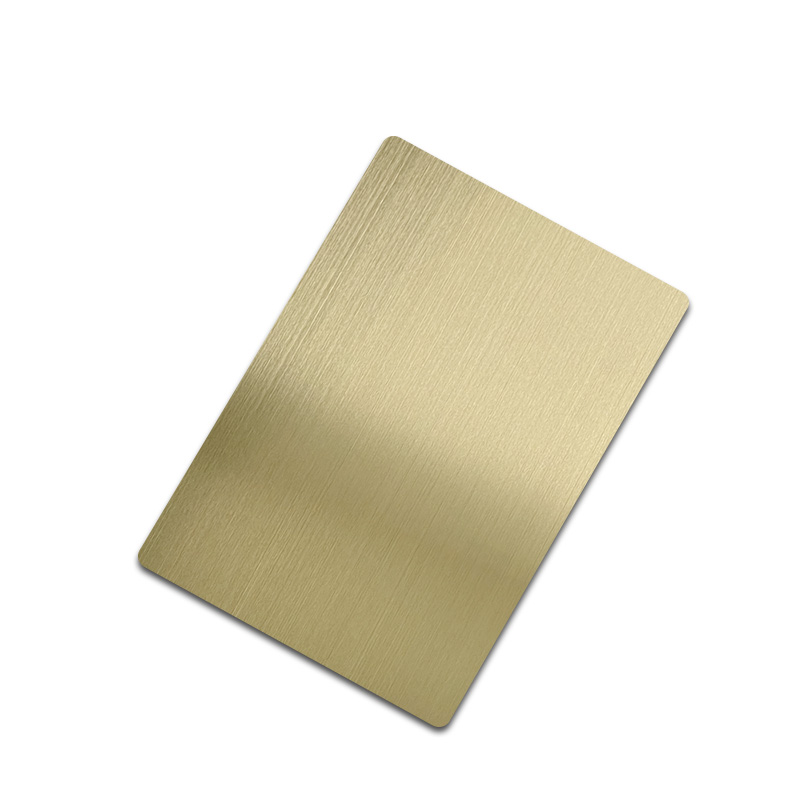

Because of the effect of the brightness, the 8K is the best choice to be applied with the color sheet. Mirror gold is the most popular produce with the customer.

Mirror surface is the most widely used in the stainless steel decorative sheet is the most common applied in the interior design, engineering projects, and the further complex finish(Etched pattern), we also welcome provide additional service such as the Laser Cutting, bending, and other process. Customized color and surface

Because the mirror titanium can reflect the pursuit of high-end, coupled with the reflection of light, so that the room presents a general feeling of the palace. So our company has more than 50,000 pieces of titanium plate orders every year.

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address

D2, Building D, Yeji Industrial Park, No. 3, Xinglong 11th Road, Chencun Town, Shunde District, Foshan City, Guangdong Province

James Zhu

Whatsapp

Whatsapp

HOME

HOME How to install the stainless steel water ripple ceiling tiles

How to install the stainless steel water ripple ceiling tiles

Let’s Talk

Let’s Talk